Deep Foam Injection

Contact your local specialist

When does Deep Foam Injection come into play?

When concrete settles, the core cause is the inability of the subgrade to support the slab. The job of the subgrade is to have enough load bearing capacity to evenly support the slab. However, when the subgrade is overburdened by the weight of the slab, the concrete can be stressed, crack, and settle further and further into the ground. In these cases it is important to lift and level the settled concrete slab. Traditional concrete raising has been able to build enough pressure to manipulate the concrete back into place. It however does not repair the subgrade that failed. That’s where Deep Foamjection of Polyurethane Foam comes into play. We would like to tell you all about Deep Foamjection with Polyurethane Foam.

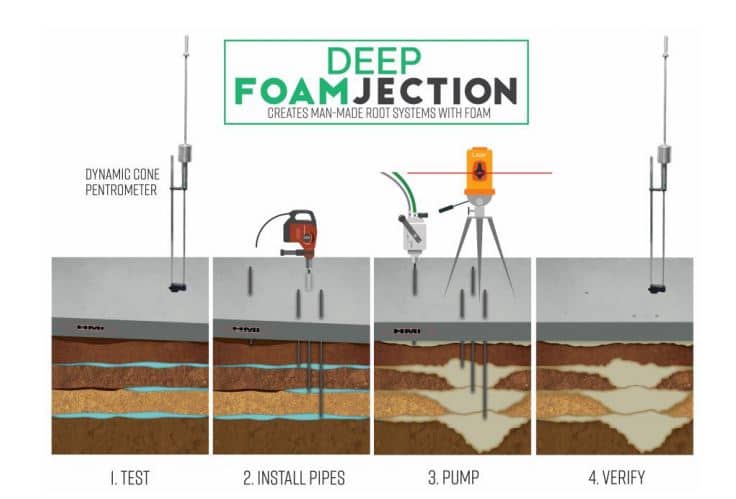

How does Deep Foam Injection work?

The process of Deep Foamjection and injecting Polyurethane Foam consists of injecting a two part polyurethane foam into weak soils to ensure soil stabilization. Installing foam deeper as a liquid, the polyurethane foam expands and pushes out on and into the weak soils. This expansion will take the path of least resistance as it moves down – voids, fisures, or weak/loose soils will provide the most common paths. As it travels, it takes the shape of a tree root. This shape is not a coincidence. Tree roots hold together loose soil. The roots grow to intertwine with the dirt and hold it together. Deep Foamjection of Polyurethane Foam creates man-made root systems.

How the foam travels and how far will depend greatly on where it can travel and the density of the compacted soil. This volume of expanded foam increases the density and strength of the soils that failed, as well as adding a solid custom installed volume of foam. With the polyurethane foam embedded in the ground and shaped like a root system, the soil density is increased and the soil locked into place.

Applications of Deep Foam Injection

The primary objective for injecting polyurethane foam into the ground is to ensure soil stabilization where the soil is unstable. The pressure built in installing this foam into the subgrade can be great enough to lift concrete. There are many applications of Deep Injection Foam, including:

- improving soil stabilization

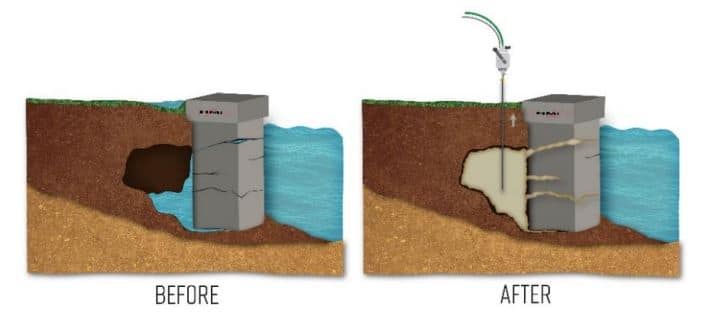

- installing ‘curtains’ to block seepage (seawall repair)

- concrete lifting and/or stabilizing such as concrete slabs, roadways, slab on grade or foundations

Material for Deep Foam Injection

The material required for the installation is a hydrofoam (hydrophobic) material called HF402. This material is designed with a slower reaction time to allow for material to pass through pipes, saturate into the subgrade, and expand into weak areas or voids. We use this material since it will set up as designed with or without water present, which is very common for subgrade applications. Also, other foams have been tested in water and have not performed as advertised. And this foam for Deep Foam Injection is environmentally friendly.

The advantages of Deep Foam Injection

- A man-made root system with foam, inspired by nature

- Binds loose soil to make it solid

- In addition to adjusting concrete slabs back into place, it repairs unstable soils

- The foundation repair creates a stronger foundation to support slabs and structures that settled

- Foam will fill weak areas, fisures and ground voids

- It increases the load bearing capacity of subgrade

- Deep Foam Injection is a permanent repair since foam never changes shape

- Does not leach chemicals into the ground

- Non-invasive since no heavy equipment or excavation is required

- Minimal downtime

Request a quote

We apply a Deep Foam Injection that binds loose soils and improves the strength to repair the weak subgrade and lift and level concrete. No project is the same. You can always contact us to request a personalised quote for your project. We are happy to help you.