Sources and Effects of Sulfates on Concrete Surfaces:

Sulfates, when present in soil, water, or other environmental elements, can have detrimental effects on concrete structures. Understanding the sources and impacts of sulfates is crucial for designing durable concrete and implementing preventive measures. Here’s an overview:

Sources of Sulfates:

- Natural Soil and Groundwater: Sulfates naturally occur in soil and groundwater. Certain regions have soils with high sulfate content, and water from these sources can introduce sulfates to concrete.

- Industrial Effluents: Industrial processes may release sulfates into the environment through effluents and emissions. Contamination from industrial sources can affect nearby concrete structures.

- Sulfate-Containing Aggregates: Aggregates used in concrete may contain sulfates. If not properly assessed and mitigated, these sulfates can contribute to the overall sulfate exposure of the concrete mix.

Effects of Sulfates on Concrete:

- Sulfate Attack: Sulfate attack is a chemical reaction between sulfates and the components of hardened concrete. The reaction can lead to the formation of expansive products, causing physical damage to the concrete matrix.

- Ettringite Formation: Sulfates can react with tricalcium aluminate, a compound in cement, to form ettringite. Ettringite formation can result in expansion and cracking of the concrete, leading to reduced strength and durability.

- Cracking and Disintegration: Sulfate attack can cause surface cracking, scaling, and overall disintegration of concrete. This is particularly problematic in environments where sulfate exposure is chronic.

- Expansion and Swelling: The reaction between sulfates and the aluminate phases in cement can lead to the formation of expansive compounds. This expansion can result in increased internal pressure, leading to cracking and deterioration.

- Loss of Strength: Sulfate attack can contribute to the loss of compressive strength in concrete. The extent of strength reduction depends on factors such as the type and concentration of sulfates, exposure conditions, and concrete composition.

- Delayed Ettringite Formation (DEF): In some cases, sulfate exposure can lead to a delayed formation of ettringite, a process known as Delayed Ettringite Formation (DEF). This can occur in concrete subjected to high temperatures and subsequently exposed to sulfates.

Preventive Measures:

- Proper Mix Design: Careful consideration of the sulfate content in aggregates and the overall mix design is essential. Using low-sulfate aggregates or incorporating supplementary cementitious materials can help mitigate sulfate-related issues.

- Sulfate-Resistant Cement: Choosing sulfate-resistant cement, such as Type V Portland cement, can enhance the resistance of concrete to sulfate attack.

- Admixtures: Specific admixtures, such as air-entraining agents or pozzolans, can be used to improve sulfate resistance. These additives can enhance the durability and mitigate the effects of sulfate exposure.

- Proper Construction Practices: Ensuring proper construction practices, such as adequate curing, sealing, and protection against sulfate-rich environments, is essential for preventing sulfate-induced damage.

- Site Drainage: Proper site drainage helps prevent the accumulation of sulfate-containing water around concrete structures. Adequate drainage reduces the risk of sulfate exposure.

- Regular Inspection and Maintenance: Regular inspection of concrete structures for signs of sulfate-induced damage allows for timely intervention and maintenance. Prompt repairs can prevent further deterioration.

Understanding the sources and effects of sulfates on concrete surfaces is integral to implementing preventive measures and ensuring the longevity and durability of concrete structures in sulfate-rich environments. If you are concerned about the effect of sulfates on your concrete project, we can help you make a plan!

Let’s delve into the specifics of the chemistry involved in sulfate attacks and Ettringite formation in concrete:

Sulfate Attack:

- Chemical Reactions:

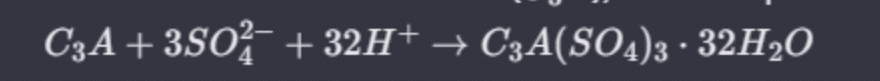

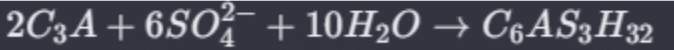

Sulfate attack involves the reaction between sulfate ions (\(SO_4^{2-}\)) and certain compounds present in the cementitious matrix of concrete. The primary compound susceptible to sulfate attack is tricalcium aluminate (\(C_3A\)), one of the phases in Portland cement.

This reaction forms calcium sulfoaluminate, known as ettringite, and results in the depletion of tricalcium aluminate. The process is accelerated in the presence of water, leading to the formation of expansive products.

- Ettringite Formation:

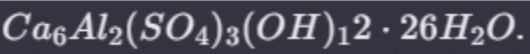

The sulfate ions react with the aluminate ions in the cement paste to form ettringite. Ettringite is a crystalline compound with the chemical formula:

![]()

– Ettringite has a tendency to occupy more space than the original components, leading to volume expansion and the development of internal pressures within the concrete.

Delayed Ettringite Formation (DEF):

High Temperatures and Delayed Formation: In some cases, the formation of ettringite is delayed, especially in situations where concrete is exposed to high temperatures during its early stages. This phenomenon is known as Delayed Ettringite Formation (DEF).

Chemical Mechanism: The initial high-temperature exposure alters the microstructure of the cement paste. The subsequent exposure to sulfates triggers the formation of ettringite at a later stage.

DEF can lead to expansion and cracking within the concrete structure, compromising its integrity.

Prevention and Mitigation:

- Use of Low \(C_3A\) Cement: Utilizing cement with a reduced tricalcium aluminate content (low \(C_3A\)) is an effective preventive measure. Low-\(C_3A\) cement minimizes the potential for sulfate attack.

- Proper Curing: Adequate curing practices help in reducing the permeability of concrete and preventing the ingress of sulfates. Proper curing provides a protective environment for the concrete during its early stages.

- Controlled Sulfate Exposure: Implementing measures to control sulfate exposure is essential. This includes using sulfate-resistant cement, avoiding contact with sulfate-rich soil or water, and ensuring proper drainage to prevent sulfate accumulation.

- Admixtures: Admixtures such as pozzolans or slag can be added to the concrete mix to mitigate the effects of sulfate attack. These materials react with sulfates, reducing the availability of sulfate ions for the detrimental reactions.

Understanding the chemistry behind sulfate attacks and Ettringite formation is crucial for designing concrete mixes that are resistant to sulfate exposure. By considering factors such as cement composition, curing practices, and sulfate-resistant additives, engineers and concrete professionals can implement strategies to enhance the durability and longevity of concrete structures in sulfate-rich environments.