The Salty Truth: How Salt Affects Concrete and Strategies for Prevention and Repair

Concrete, a robust and widely used building material, is not immune to the corrosive effects of salt. In regions where de-icing salts are regularly employed to combat winter weather, concrete structures face increased vulnerability. This blog post will delve into the chemistry behind salt damage to concrete, identify the signs of deterioration, explore preventive measures like sealing, and discuss repair options such as patching and sectional replacement, weighing the advantages and disadvantages of each.

Chemistry of Salt Damage

The chemistry of salt-induced concrete damage is a complex interplay of factors. When de-icing salts, such as sodium chloride, come into contact with concrete surfaces, they can penetrate the porous structure. The salt dissolves in water, forming a saline solution that infiltrates the concrete’s capillaries. During freeze-thaw cycles, the water expands as it freezes, exerting pressure on the concrete. The repeated cycle of freezing and thawing, coupled with the presence of salt, contributes to the breakdown of the concrete matrix.

Signs of Salt Damage

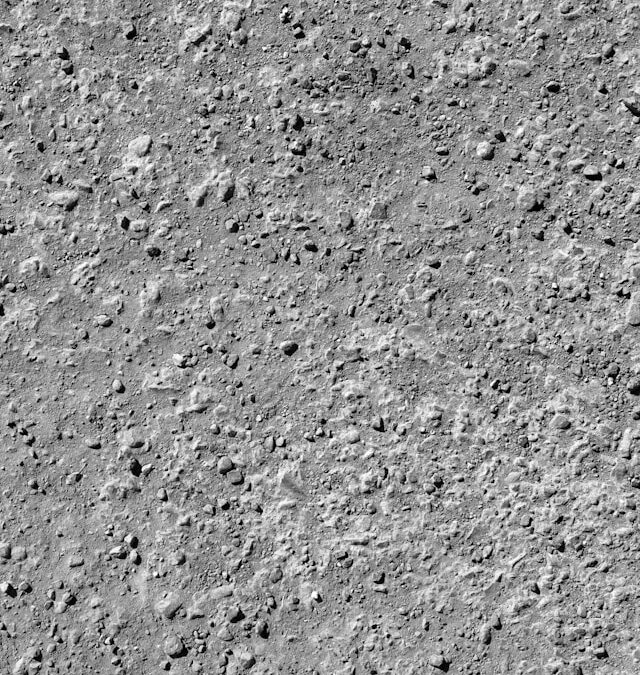

Identifying salt damage early is crucial for effective intervention. Common signs include surface scaling, where the top layer of the concrete peels or flakes away, exposing the aggregate beneath. Cracking, spalling (the breaking off of small pieces), and the formation of white, powdery deposits known as efflorescence are also indicative of salt-induced damage.

Prevention through Sealing

One effective strategy to mitigate salt damage is the application of sealers. Sealers create a protective barrier on the concrete surface, preventing water and salts from infiltrating the pores. Penetrating sealers, which penetrate the concrete and chemically react to form a barrier, are particularly effective. Regular reapplication may be necessary, especially in areas with heavy salt use, to maintain the sealer’s protective properties.

Repairing Salt Damage

When salt damage has occurred, prompt and appropriate repair is essential to prevent further deterioration. Two common methods are patching and sectional replacement.

-

Patching:

Advantages

- Cost-effective and less labor-intensive than sectional replacement.

- Suitable for addressing localized damage and small areas of deterioration.

Disadvantages

- May result in a patchwork appearance, especially on larger surfaces.

- Not ideal for extensive or widespread damage.

Sectional Replacement

Advantages

- Offers a more comprehensive and uniform solution for extensive damage.

- Allows for addressing structural issues that may not be apparent at the surface.

Disadvantages

- Higher cost and greater time investment compared to patching.

- Disruption to the area during the replacement process.

Understanding the chemistry of salt damage to concrete is the first step in formulating effective preventive measures and repair strategies. Sealing, with its protective barrier against salt infiltration, stands out as a proactive approach. In the event of damage, the choice between patching and sectional replacement depends on the extent and severity of the deterioration. Each method has its advantages and disadvantages, and the decision should be tailored to the specific circumstances. Ultimately, a combination of proper maintenance, timely intervention, and informed repair choices can help concrete structures withstand the corrosive effects of salt and maintain their longevity.

Chemistry of Salt Damage (Deep Dive):

The interaction between de-icing salts and concrete involves several chemical processes that contribute to the deterioration of the material. The primary culprit is often sodium chloride, commonly used as road salt to melt ice and snow during winter. The chemical reactions can be broken down into the following steps:

- Salt Dissolution: When sodium chloride comes into contact with the surface of concrete, it dissolves in water. The resulting solution is a mixture of sodium ions (Na+) and chloride ions (Cl-) suspended in water.

- Ion Migration: The dissolved ions, particularly chloride ions, can migrate into the porous structure of concrete through capillary action. Concrete is inherently porous, with a network of capillaries and pores that allow the movement of water and ions.

- Capillary Absorption: The capillaries within the concrete act like tiny channels, facilitating the absorption of the saline solution. As the water in the solution is absorbed into the concrete, it carries the chloride ions with it.

- Chemical Reactions with Cementitious Materials: Once inside the concrete matrix, chloride ions can initiate chemical reactions that contribute to the breakdown of the material. Chloride ions can react with compounds in the cement, such as calcium hydroxide (Ca(OH)₂), forming calcium chloride (CaCl₂) and other compounds.

These reactions can lead to the formation of expansive products that contribute to internal pressure within the concrete, exacerbating the damage during freeze-thaw cycles.

These reactions can lead to the formation of expansive products that contribute to internal pressure within the concrete, exacerbating the damage during freeze-thaw cycles. - Freeze-Thaw Damage: The penetration of water and chloride ions into the concrete, combined with freeze-thaw cycles, is a critical factor in the deterioration process. When the absorbed water freezes, it expands, exerting pressure on the surrounding concrete. This expansion can cause microcracks and fractures, further compromising the structural integrity of the material.

Understanding these chemical processes underscores the importance of addressing salt damage comprehensively. Prevention through sealing is one effective strategy to minimize the penetration of salts into the concrete matrix. The protective barrier created by sealers helps to mitigate the impact of chloride ions and water, reducing the likelihood of chemical reactions and freeze-thaw damage.

In summary, the chemistry of salt damage involves the dissolution of salt, migration of ions into the concrete, chemical reactions with cementitious materials, and the destructive effects of freeze-thaw cycles. This understanding is crucial for developing effective preventive measures and informed repair strategies to protect concrete structures from the corrosive impact of de-icing salts.